Why would a single-phase motor hum but not start?

A single-phase motor making a buzzing sound but not starting may be caused by various reasons, such as power supply issues, mechanical problems, capacitor issues, etc.

Single-phase motors are an integral part of both residential and commercial applications, powering everything from small household appliances to various types of industrial machinery. Sometimes single-phase motors may encounter issues during the startup process, such as humming without starting. This article will discuss the reasons for this problem and how to troubleshoot it to minimize downtime, extend the motor's lifespan, and improve efficiency.

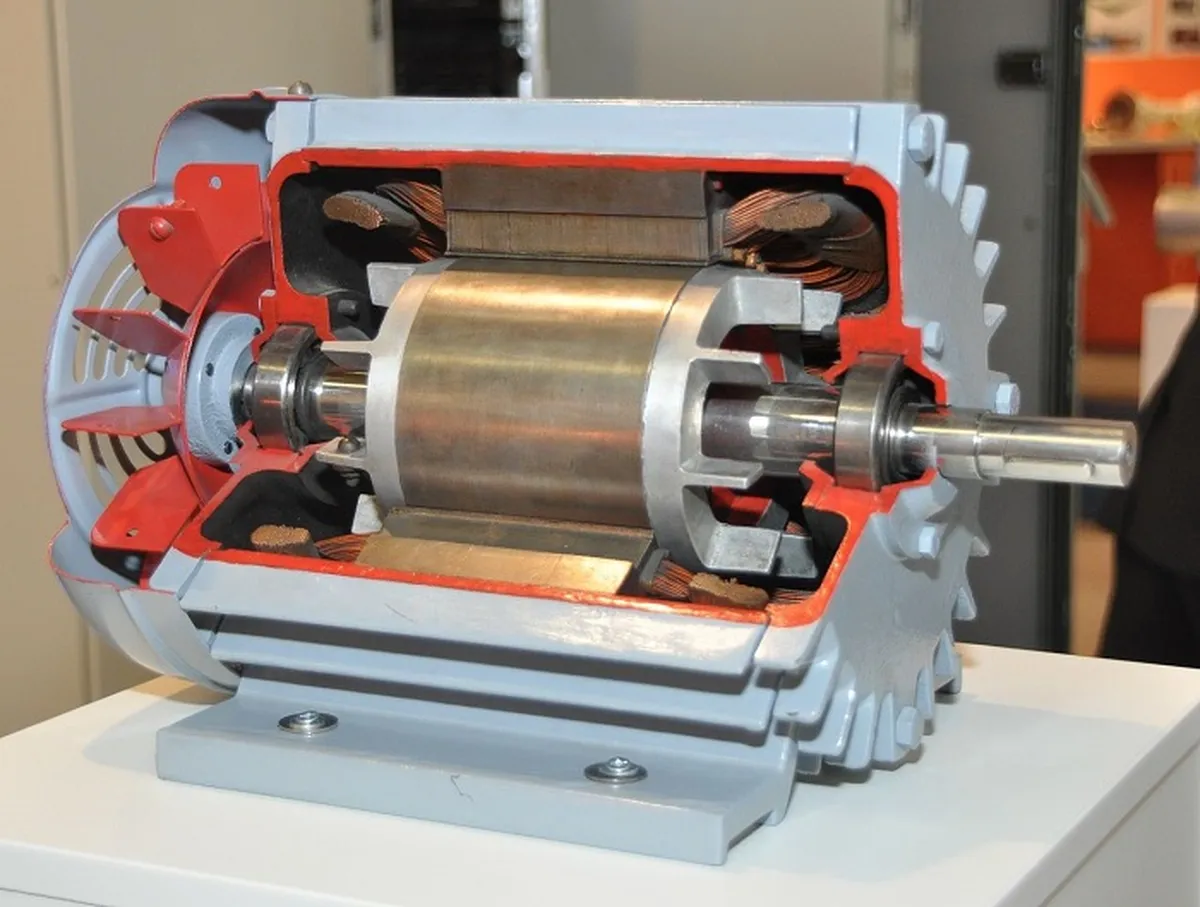

Understanding Single-Phase Motors

Single-phase motors are a crucial component in various applications, ranging from household appliances to industrial equipment. These motors operate on a single-phase power supply and are known for their simplicity, cost-effectiveness, and widespread availability. Unlike their three-phase counterparts, single-phase motors do not naturally start on their own due to the absence of a rotating magnetic field.

Construction

The construction of a single-phase induction motor is notably similar to that of a three-phase induction motor, featuring a squirrel cage rotor and a stator wound for single-phase supply. A distinctive characteristic is the inclusion of a starting winding in the stator, which is pivotal for initiating motor operation. This starting winding is utilized alongside various starting methods to overcome the initial inertia and enable the motor to start.

Starting Methods

Several methods have been developed to start single-phase motors effectively, addressing their inherent inability to self-start. These methods include the use of a shaded pole, split-phase, capacitor-start, and permanent split capacitor mechanisms, each with its unique approach to generating a rotating magnetic field necessary for startup.

Causes of Humming but Not Starting

As a key component in household appliances and industrial equipment, a unidirectional motor emitting a buzzing sound but not starting can be very troublesome and even reduce work efficiency. There are many reasons for this problem, such as power supply issues, mechanical failures, starter mechanism malfunctions, or capacitor failures, which can all lead to this problem.

Capacitor Malfunctions

-

Start Capacitor Failure

The start capacitor plays a vital role in providing the initial surge of energy required to start the motor. Failure of this component, often due to overheating, can prevent the motor from starting while producing a humming sound. Start capacitors are not designed for continuous operation and can overheat if left in the circuit too long, leading to failure.

-

Run Capacitor Issues

Similar to the start capacitor, the run capacitor is essential for continuous operation. Problems with the run capacitor can lead to the motor humming but not starting, particularly under load conditions. Replacing or troubleshooting the run capacitor may resolve this issue.

-

Capacitor Discharge Safety

To protect the start relay contacts from damage due to high voltage discharge from the start capacitor, a bleed resistor across the terminals can be employed. This resistor helps dissipate the energy, preventing damage that could otherwise lead to starting issues.

Centrifugal Switch Issues

Some single-phase motors incorporate a centrifugal switch that helps disengage the starting winding once the motor reaches a certain speed. If the centrifugal switch becomes stuck or fails to operate correctly, the starting winding remains engaged, preventing the motor from transitioning to the running mode.

Power Supply Issues

-

Voltage Drop

Insufficient voltage reaching the motor can result in a humming sound without the motor starting. Voltage drop can occur due to undersized wiring, long cable distances, or excessive electrical loads on the same circuit. Low voltage reduces the starting torque, preventing the motor from overcoming its inertia.

-

Weak Power Supply

Inadequate power supply capacity or a weak electrical grid can also lead to the motor humming but not starting. If the available power is not sufficient to meet the motor's starting requirements, it will struggle to start, resulting in a humming sound.

Mechanical Issues

-

High Friction or Mechanical Jam

Excessive mechanical friction, such as bearing problems, misalignment, or a jammed rotor, can prevent the motor from starting even though it produces a humming sound. The increased resistance inhibits the motor from reaching the required rotational speed.

-

Excessive Load

An overloaded motor may struggle to start, causing it to hum without successfully entering the running mode. If the load on the motor exceeds its rated capacity, it may require additional torque that the motor cannot provide.

-

Bearing Damage

Damaged or seized bearings can also prevent a motor from starting while producing a humming noise. Bearings facilitate smooth operation of the motor, and their failure can impede the motor's ability to start.

Troubleshooting and Solutions

Capacitor Replacement

If the issue lies with a faulty or incorrect capacitor, replacing it with a properly sized and functioning one can resolve the problem. Consult the motor's specifications or seek professional assistance to ensure the appropriate capacitor replacement.

Centrifugal Switch or Starting Capacitor Relay Repair

In cases where the starting mechanism is at fault, repairing or replacing the centrifugal switch or starting capacitor relay can restore proper motor functionality. Professional expertise may be required for accurate diagnosis and repair.

Addressing Power Supply Issues

Addressing power supply problems involves ensuring proper voltage levels and electrical connections. Consult an electrician to assess and rectify any issues related to voltage drop, weak power supply, or inadequate wiring.

Mechanical Inspection and Maintenance

Perform a thorough mechanical inspection of the motor, including bearings, alignment, and load conditions. Lubrication, realignment, or load reduction may be necessary to eliminate mechanical issues causing the motor to hum but not start.

Conclusion

When a single-phase motor emits a buzzing sound and fails to start, it may be caused by various factors. By troubleshooting the issue and identifying the root cause, appropriate solutions can be implemented to restore the motor to normal operation.

Leave a Comment