Why induction motors are preferred for industrial drives?

Induction motors are widely used in industry due to their ruggedness, high efficiency, and wide power range.

In the realm of industrial machinery and automation, the choice of motor for driving various processes and systems is crucial. Induction motors have long been the preferred choice for industrial drives due to their numerous advantages and suitability for a wide range of applications. Their robust construction, reliability, efficiency, and cost-effectiveness make them the go-to option for powering machinery and equipment in industrial settings. This article delves into the reasons why induction motors are highly preferred for industrial drives, examining their key features and benefits in depth.

Advantages of Induction Motors for Industrial Drives

-

Robust Construction and Durability

Induction motors are known for their sturdy and robust construction, making them well-suited for demanding industrial environments. The key design features contributing to their durability include:

- Rugged Enclosure

Induction motors are typically housed in a robust enclosure that protects the internal components from dust, moisture, and mechanical stress. This ensures their longevity and reliable operation even in harsh conditions.

- Simple Design

With fewer moving parts, induction motors have a relatively simple design, reducing the likelihood of mechanical failures and the need for frequent maintenance or repairs.

- Rugged Enclosure

-

Wide Range of Power and Speed

Industrial applications often require motors with varying power ratings and speed ranges to meet specific operational requirements. Induction motors excel in this regard due to:

- Power Range

Induction motors are available in a wide range of power ratings, from a few watts to several megawatts. This flexibility allows for the selection of motors suited to the specific power demands of various industrial applications.

- Speed Control

Induction motors can be easily controlled and regulated to provide variable speeds as needed. Speed control can be achieved through the use of variable frequency drives (VFDs) or other control methods, enabling precise control over motor speed and enhancing operational efficiency.

- Power Range

-

Reliability and Low Maintenance

Industrial processes often require continuous operation, and any unplanned downtime can lead to substantial financial losses. Induction motors offer reliability and low maintenance requirements, ensuring uninterrupted operation:

- Improved Motor Design

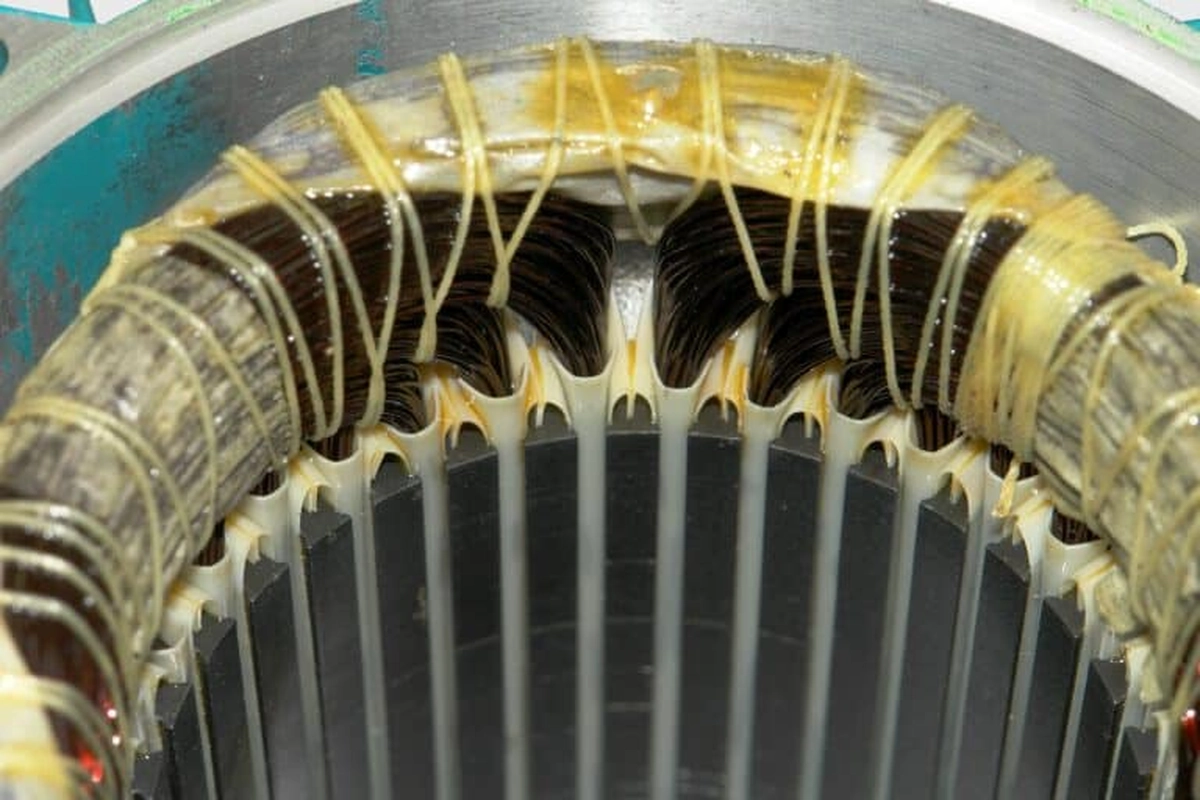

Advancements in motor design and materials have led to increased efficiency in induction motors. Modern designs incorporate features such as optimized stator and rotor configurations, reduced losses, and improved ventilation systems, resulting in higher overall motor efficiency.

- High Power Factor

Induction motors typically exhibit a high power factor, which is beneficial for industrial applications. A high power factor reduces reactive power requirements, resulting in improved energy efficiency and reduced electricity costs.

- Improved Motor Design

-

Reliability and Low Maintenance

Industrial processes often require continuous operation, and any unplanned downtime can lead to substantial financial losses. Induction motors offer reliability and low maintenance requirements, ensuring uninterrupted operation:

- Minimal Wear and Tear

The absence of brushes and commutators in induction motors eliminates the need for regular maintenance associated with brush replacement, reducing downtime and maintenance costs.

- Robust Rotor Construction

The squirrel cage rotor design of induction motors contributes to their reliability. The absence of slip rings and brushes eliminates potential failure points, enhancing the motor's overall reliability and reducing the need for frequent repairs.

- Minimal Wear and Tear

Cost-Effectiveness

Cost considerations play a significant role in industrial applications. Induction motors offer several cost-related benefits:

- Lower Initial Investment

Compared to other motor types, induction motors typically have a lower initial purchase cost, making them an economical choice for industrial applications.

- Energy Efficiency

The high efficiency of induction motors translates into lower energy consumption, resulting in reduced operating costs over the motor's lifespan.

- Reduced Maintenance Expenses

The robust construction, minimal maintenance requirements, and extended operational life of induction motors contribute to cost savings by reducing maintenance expenses and minimizing downtime.

Conclusion

Induction motors have established themselves as the preferred choice for industrial drives due to their robust construction, wide power and speed range, high efficiency, reliability, and cost-effectiveness. Their ability to withstand demanding industrial environments, coupled with their low maintenance requirements and extended operational life, makes them an ideal option for powering machinery and equipment. When considering industrial applications, you can confidently rely on induction motors to deliver consistent and efficient performance, ensuring the smooth operation of industrial processes.

Leave a Comment