What are the different types of electric motors and what are they used for?

There are generally two types of motors, AC motor, and DC motor.

Electric motors are ubiquitous in modern society, powering a wide range of devices and machinery. They are essential for converting electrical energy into mechanical energy, enabling various applications across industries. Understanding the different types of electric motors and their respective applications is essential for appreciating their significance in diverse industries. This article aims to provide a comprehensive overview of the different types of electric motors and their respective uses.

Introduction to Electric Motors

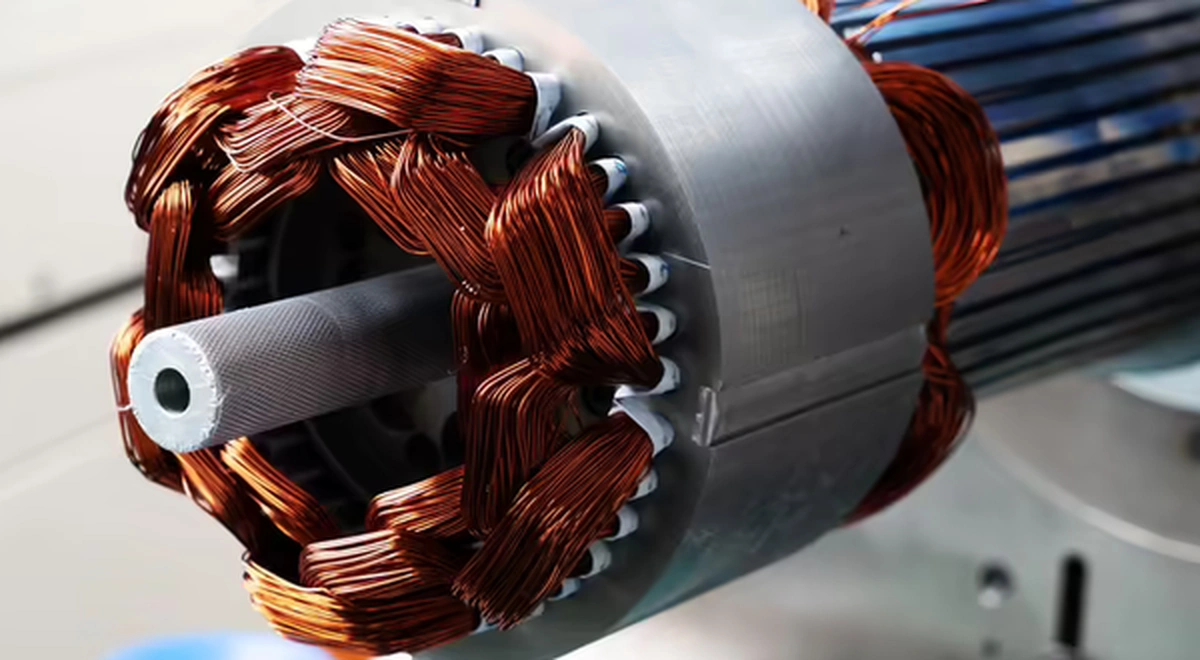

Electric motors are electromechanical devices that convert electrical energy into mechanical energy, generating rotational motion. They operate based on the principles of electromagnetic induction, where the interaction between magnetic fields and electric currents produces motion. Electric motors come in a variety of types, each tailored to specific applications and operating conditions.

I. DC Motors

DC motors operate using direct current and are available in various configurations. They offer precise control and are commonly used in applications requiring speed regulation. DC motors are used in a wide range of applications, including automotive systems, industrial automation, consumer electronics, and renewable energy systems. They power devices such as electric vehicles, actuators, servo mechanisms, and computer peripherals. Here are the primary types of DC Motors:

Brushed DC Motors

Brushed DC motors use a rotating commutator and brushes to switch the direction of current flow in the armature windings. They are widely used in applications such as power tools, appliances, and automotive systems.

Brushless DC Motors (BLDC)

BLDC motors employ electronic commutation instead of brushes and commutators. They offer improved reliability, efficiency, and lifespan compared to brushed DC motors. BLDC motors find application in robotics, automated machinery, pumps, HVAC systems, electric vehicles, and drones. They are also used in household appliances such as blenders, vacuum cleaners, and power tools.

II. AC Motors

AC motors run on alternating current and are highly versatile, efficient, and widely used in industrial and commercial applications. Below are the main types of AC motors:

Induction Motors

Induction motors are the most common type of AC motor. They operate based on electromagnetic induction and do not require external commutation. Induction motors find application in a myriad of industries, including HVAC systems, pumps, fans, compressors, conveyor belts, and machine tools. They are also used in household appliances such as washing machines, refrigerators, and air conditioners.

Synchronous Motors

Synchronous motors operate at a fixed speed and maintain synchronism with the frequency of the power supply. Synchronous motors are utilized in applications such as industrial drives, robotics, synchronous generators, and synchronous condensers. They are also used in applications requiring precise speed control, such as clocks, turntables, and synchronous motors in electric clocks.

Servo Motors

Servo motors are high-performance motors that offer precise control over position, speed, and torque. They are commonly used in robotics, CNC machines, automation systems, and other applications requiring precise motion control.

Stepper Motors

Stepper motors provide precise incremental motion by dividing a full rotation into steps. They are widely used in 3D printers, CNC machines, robotics, and automation systems that require accurate positioning and control.

III. Specialized Motors

Apart from the standard DC and AC motors, certain specialized motors serve specific purposes in unique applications. Here are a few examples:

Linear Motors

Linear motors convert electrical energy into linear motion without the need for rotary-to-linear conversion mechanisms. They find applications in high-speed transportation systems, positioning stages, and magnetic levitation systems.

IV. Conclusion

Understanding the different types of electric motors and their applications is vital for selecting the appropriate motor for a specific task. From DC motors like brushed and brushless types to AC motors including induction, synchronous, servo, and stepper motors, each motor type offers unique advantages suited to particular applications. By considering the specific requirements of a project or application, you can make informed decisions and leverage the capabilities of electric motors to achieve efficient and optimized performance in their respective fields.

Leave a Comment