How to check an electric motor's short circuit or open circuit?

Performing regular checks for open and short circuit conditions in electric motors is a good measure that can lead to extended motor life, reduced downtime, and increased safety.

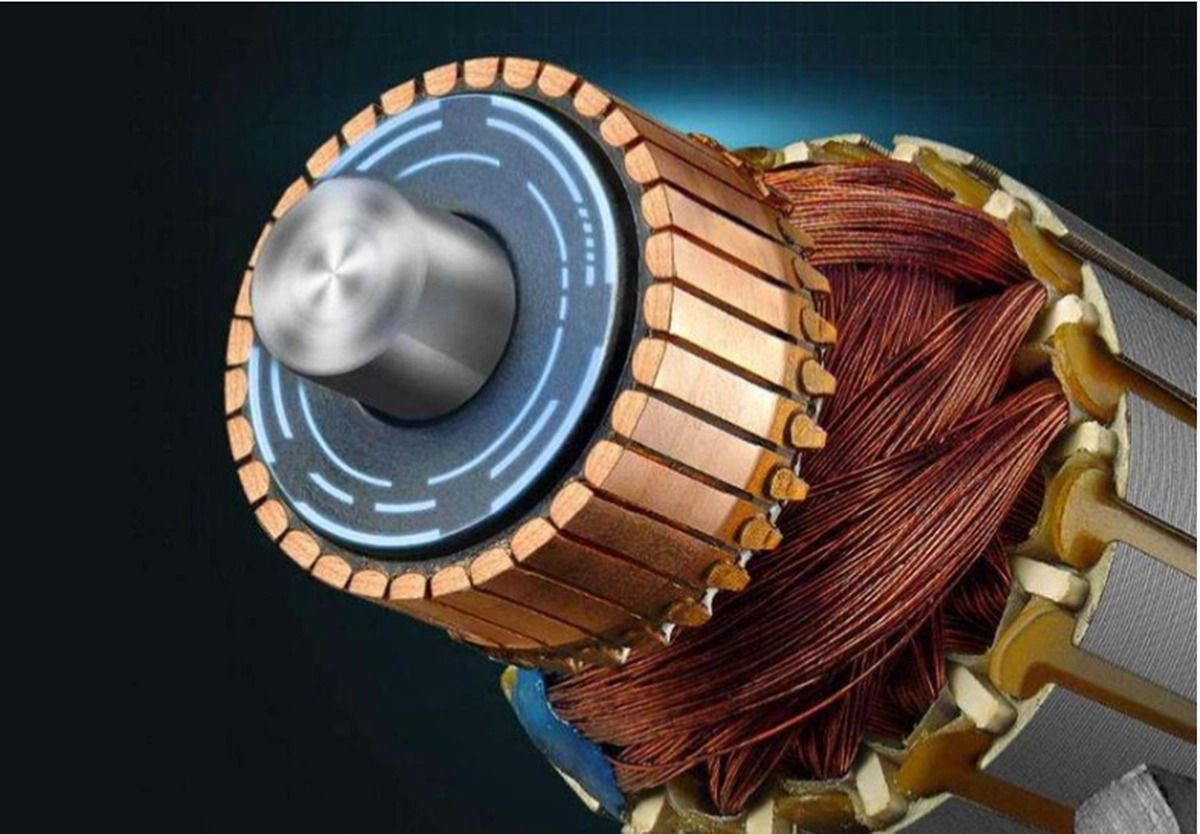

Electric motors are essential components in various applications, powering machinery and equipment across industries. However, like any electrical device, motors can experience faults such as short circuits or open circuits. Detecting these issues is crucial for troubleshooting and ensuring the motor's optimal performance. In this comprehensive guide, we will discuss how to check for short circuits or open circuits in electric motors, providing you with a step-by-step process to identify and address these problems effectively.

Understanding Short Circuits and Open Circuits

-

Short Circuits

A short circuit occurs when a low-resistance path is created between two points in an electrical circuit, bypassing the intended load. This can lead to excessive current flow, overheating, damage to components, and potential safety hazards.

-

Open Circuits

An open circuit refers to a break or discontinuity in the electrical path, preventing current flow in the circuit. This can result in the motor not functioning or operating abnormally.

Tools Required for Testing

Before proceeding with the testing process, gather the following tools:

- Multimeter: Used to measure voltage, current, and resistance.

- Insulation Resistance Tester: Utilized to measure the insulation resistance of motor windings.

- Continuity Tester: Helps identify the continuity of electrical connections.

Safety Precautions

Working with electrical circuits and motors involves inherent risks. Prioritize safety by following these precautions:

- Disconnect the motor from the power source before performing any tests.

- Use appropriate personal protective equipment, such as gloves and safety glasses.

- Ensure a safe working environment, free from potential electrical hazards.

Testing for Short Circuits

-

Disconnect the Motor

Disconnect the motor from the power source and ensure it is isolated.

-

Visual Inspection

Conduct a thorough visual inspection of the motor and its wiring. Look for any signs of physical damage, loose connections, or burnt components.

-

Continuity Testing

Using a continuity tester or multimeter set to continuity mode, check for continuity between the motor windings and the motor case. If continuity exists, it indicates a short circuit.

-

Resistance Measurement

Measure the resistance between each motor winding using a multimeter. Compare the measured values with the motor's specifications or reference values provided by the manufacturer. Abnormally low resistance readings may indicate a short circuit.

Testing for Open Circuits

-

Disconnect the Motor

Ensure the motor is disconnected from the power source.

-

Visual Inspection

Inspect the motor and wiring for any visible signs of damage, loose connections, or broken wires.

-

Continuity Testing

Using a continuity tester or multimeter, check for continuity between each end of the motor windings. If there is no continuity, it indicates an open circuit.

-

Insulation Resistance Testing

Use an insulation resistance tester to measure the insulation resistance of the motor windings. Compare the readings with the motor's specifications. Lower than expected resistance values suggest an open circuit or insulation breakdown.

Additional Considerations

-

Thermal Imaging

Thermal imaging cameras can help identify abnormal heat patterns in the motor, which may indicate short circuits or open circuits. High temperatures at specific areas can pinpoint potential issues.

-

Professional Assistance

If you are uncertain about performing tests or interpreting results, it is advisable to consult a qualified electrician or motor specialist. Theycan provide expertise and guidance in diagnosing and resolving motor faults.

Conclusion

Checking for short circuits or open circuits in electric motors is crucial for maintaining their performance and preventing potential hazards. By following the above steps and using the appropriate tools, you can effectively diagnose these issues. Remember to prioritize safety throughout the testing process and seek professional assistance when needed.

Leave a Comment