How many volts does an AC motor require?

The voltage requirement of an AC motor is influenced by factors such as motor design, application, and power grid standards. Different countries or regions may have different voltage standards.

When it comes to AC (Alternating Current) motors, one common question that arises is the voltage requirement. Understanding the voltage specifications of an AC motor is crucial for proper installation, operation, and compatibility. In this article, we will delve into the factors influencing the voltage requirements of AC motors, their typical voltage ratings, and the importance of adhering to these specifications.

Factors Affecting AC Motor Voltage Requirements

-

Motor Design

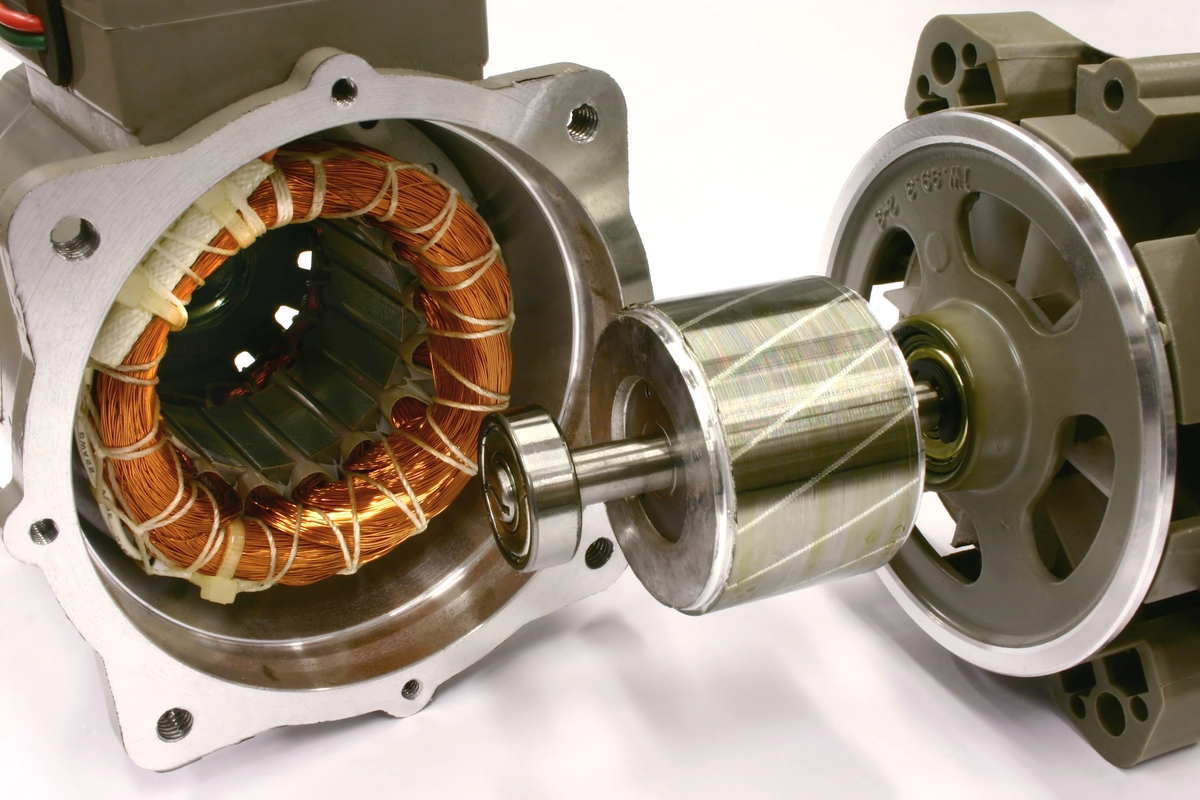

The voltage requirement of an AC motor is primarily determined by its design characteristics, including the number of windings, coil configurations, and wire materials used. These factors influence the motor's impedance and the amount of voltage required to generate the desired magnetic field.

-

Motor Application

The application of the AC motor also plays a significant role in determining its voltage requirement. Different applications may have specific voltage standards or operational constraints that dictate the choice of motor voltage. Factors such as motor size, power requirements, and starting torque can influence the voltage selection.

-

Power Grid Standards

The voltage available from the power grid or electrical supply system also affects the voltage requirement of AC motors. Different regions or countries may have varying standard voltage levels, such as 110V, 220V, 380V, or 480V. AC motors are designed to operate within these standard voltage ranges.

Typical Voltage Ratings for AC Motors

-

Low Voltage AC Motors

Low voltage AC motors typically operate within the range of 110V to 240V. These motors are commonly found in household appliances, small machinery, and portable devices. The lower voltage requirement ensures compatibility with standard residential or low-power electrical outlets.

-

Medium Voltage AC Motors

Medium voltage AC motors generally operate within the range of 240V to 600V. These motors are commonly used in industrial applications, HVAC systems, and larger machinery. The higher voltage requirement allows for greater power output and is compatible with commercial and industrial electrical systems.

-

High Voltage AC Motors

High voltage AC motors operate above 600V. These motors are typically employed in heavy industrial applications, such as large-scale machinery, pumps, compressors, and power generation systems. High voltage operation enables higher power transmission efficiency over long distances and is regulated by specific electrical codes and safety precautions.

Importance of Adhering to Voltage Specifications

-

Performance and Efficiency

Using the correct voltage rating is critical for ensuring optimal motor performance and efficiency. Operating an AC motor at a voltage higher or lower than its specified rating can lead to various issues, including decreased efficiency, overheating, increased wear and tear, and potential motor failure.

-

Safety Considerations

Adhering to the voltage specifications of an AC motor is essential for maintaining a safe working environment. Operating a motor at an incorrect voltage can pose safety hazards, such as electrical shocks, fire risks, or damage to other electrical components within the system.

-

Compliance with Standards

Meeting the recommended voltage requirements ensures compliance with industry standards and regulations. Non-compliance can result in legal implications, voided warranties, or issues during inspections or certifications.

Determining the Voltage Requirement

Determining the precise voltage requirement for an AC motor involves consulting the motor's manufacturer specifications, data sheets, or nameplate information. These documents provide valuable information, including the rated voltage, current, frequency, and other technical details specific to the motor.

Voltage Conversion and Compatibility

In situations where the available power supply voltage does not match the motor's voltage requirement, voltage conversion techniques such as transformers or voltage regulators can be employed to adjust the voltage to the required level. However, caution must be exercised to ensure the compatibility and suitability of such conversion methods.

Conclusion

The voltage requirement of an AC motor is influenced by factors such as motor design, application, and power grid standards. AC motors are available invarious voltage ratings, including low voltage, medium voltage, and high voltage, catering to different applications and power requirements. Adhering to the specified voltage requirements is crucial for achieving optimal motor performance, ensuring safety, and complying with industry standards. When selecting or installing an AC motor, it is best to consult the manufacturer for specifications and seek professional advice to ensure the correct voltage for your application, thereby maximizing the efficiency, lifespan, and overall operational reliability of the motor. Lunyee has many years of experience in the field of electric motors. If you have any questions related to electric motors, our technical team will be happy to help you solve any problems.

Leave a Comment