How many moving parts does an electric motor have?

The main moving parts of an electric motor are composed of a rotor, a shaft, and bearings. A DC motor has additional moving parts such as a commutator and brushes.

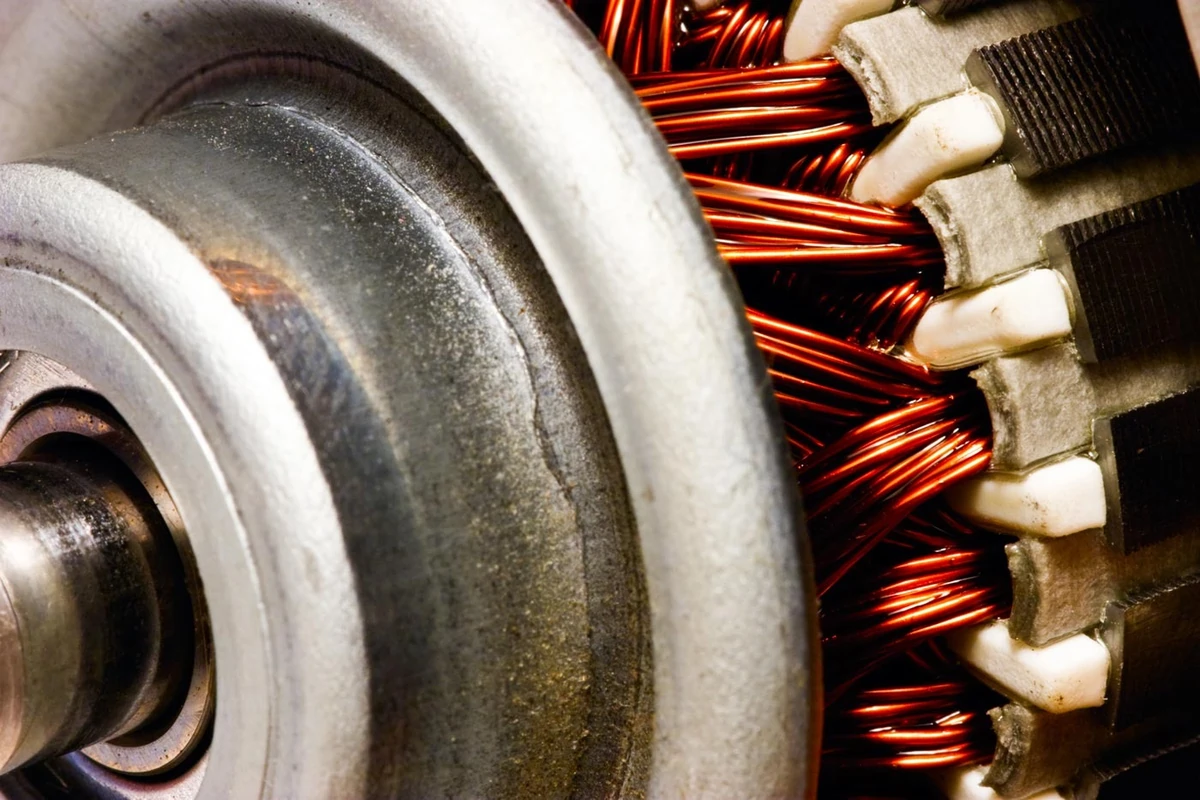

Electric motors play an indispensable role in our daily lives, powering everything from household appliances to industrial machinery. To gain insight into their maintenance requirements, longevity, and efficiency, one must consider the number of moving parts they contain. This article delves into the components within electric motors, specifically focusing on moving parts.

The Main Moving Parts of an Electric Motor

-

Stator

The stator is the stationary part of an motor and is composed of a core made of laminated steel sheets. It houses the stator windings, which produce a magnetic field when energized.

-

Rotor

The rotor is the rotating part of the motor and is connected to the motor's output shaft. It is designed to turn the shaft to deliver mechanical power. It is typically constructed using laminated steel sheets and carries the rotor windings or permanent magnets, depending on the motor type.

-

Bearings

Bearings are crucial components that support the rotor shaft and facilitate its smooth rotation. They support the rotating shaft, reducing friction and wear over time. While not a singular moving part of their own, bearings are integral to the motion within the motor. Electric motors typically employ two types of bearings: ball bearings and sleeve bearings.

-

The Commutator (DC Motors)

In a DC motor, another moving part is the commutator. It partners with the brushes to maintain the direction of the electric current and thus the magnetic field. The commutator rotates with the motor's shaft, and while its function is more electrical than mechanical, it remains a moving part.

-

The Brushes (DC Motors)

Brushes, found in many types of DC motors, are in physical contact with the commutator, sliding against it to form an electrical connection as the rotor spins. Brushes move back and forth, albeit to a tiny degree, but considering their function and the stress they endure, brushes are often accounted for as moving parts in DC motors.

Other Considerations

AC Motors

In AC motors, especially induction motors, there are generally fewer moving parts than in their DC counterparts. An induction motor typically has no brushes or commutators. The main moving component is the rotor itself, with the bearings being the other moving parts due to their role in the rotor's rotation.

Stepper Motors and Servo Motors

Specialty motors, such as stepper motors and servo motors, have a similar count of moving parts. Stepper motors move in precise increments and have rotors and bearings. Servo motors, used for more precise control, also consist of rotors and bearings as primary moving parts. Some complex servo systems may have additional moving parts for greater control mechanisms.

The Impact of Moving Parts

The number of moving parts in an electric motor affects its efficiency, reliability, and maintenance needs. Motors with fewer moving parts tend to be more reliable and require less upkeep. This is a significant advantage of AC induction motors over DC motors with brushes and commutators.

Conclusion

Electric motors consist of various moving parts that work in harmony to convert electrical energy into mechanical energy. The rotor, shaft, bearings, and, in the case of DC motors, the commutator and brushes are key components responsible for the motor's operation. DC motors have additional moving parts like the commutator and brushes. The exact number of moving parts can vary depending on the motor type, design, and the inclusion of components such as fans or gears that may be integrated into the motor's operation. Understanding these moving parts and their maintenance requirements is vital for maximizing motor performance and ensuring its longevity. By properly maintaining and caring for these components, you can optimize the efficiency, reliability, and overall functionality of electric motors across a wide range of applications.

Leave a Comment