Methods to choose a right robotic motor

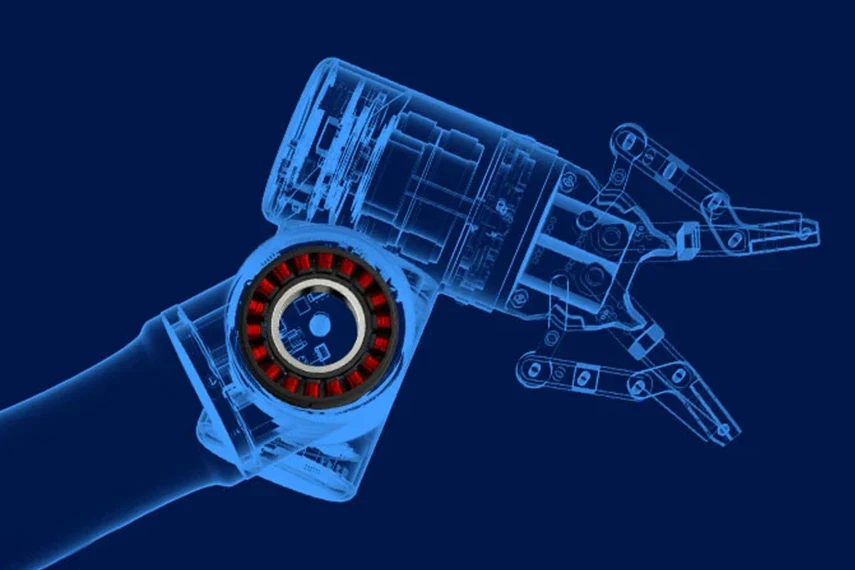

Selecting the right motor for robotics applications is crucial. Three main types of motors are used in robotics: DC motors, stepper motors, and servo motors. Torque requirements, speed, and control method are essential factors to consider when selecting a motor. By evaluating these factors carefully, you can choose a motor that provides optimal performance and reliability for your robotic system.

In recent years, the robotics industry has been growing along with economic and technological development. The demand for motors that can drive robot motion is also growing rapidly. Choosing the right motor for your robotics application is very important, and in this article we will discuss the key factors to consider when choosing the perfect motor for your robotics application, including motor type, torque requirements, speed, and control method.

Common types of motors for robotics applications

There are three main types of motors used in robotics applications: DC motors, servo motors, and stepper motors. Each motor type has its own unique advantages and disadvantages, so understanding their characteristics will help you make an informed decision.

- DC Motor

DC Motors are further divided into two types: brushed DC motors and brushless DC motors.

Brushed DC motors are simple, cost-effective, and offer a wide range of torque and speed capabilities. However, due to the use of brushes, they generate more noise and require regular maintenance, making them suitable for low-cost, low-precision robotics applications.

Brushless DC motors, also known as BLDC motors, offer higher efficiency, longer life, and less maintenance due to the absence of brushes. However, they require more sophisticated drive electronics and are therefore suitable for high performance robotics applications that require high precision, efficiency, and reliability.

- Stepper motors

Stepper motors offer excellent repeatability and positioning accuracy, making them ideal for applications that require precise control, such as CNC machines and 3D printers, but they are less efficient and can generate more noise.

- Servo Motor

Servo motors enable precise control of motion and positioning, and also offer high reliability and durability, making them ideal for robotics applications that require precise control of movement and positioning, high speed and torque, closed-loop control, flexible operation, and high reliability, such as industrial robots, mobile robots, surgical robots, and hobbyist projects.

Considerations

It is critical to select a motor with sufficient torque to handle the load requirements of the robot application. Therefore, the weight of the robot and its payload, the mechanical efficiency of the system (gearing, friction, etc.), and the acceleration and deceleration of the required motion need to be considered. Regardless of what factors are required, it is important to calculate the torque required for your robot application and select a motor that meets or exceeds this requirement to ensure optimal performance and prevent motor damage.

- The motor speed determines the movement speed of the robot. However, if the motor speed is too fast, the corresponding motor torque will be reduced. It is critical to select a motor that provides the necessary balance of speed and torque for your application. Gearboxes can be used to adjust the speed and torque characteristics of the motor for greater flexibility in meeting the specific requirements of your application.

- The motor control method plays a critical role in the overall performance and functionality of the robot system. It is also an important factor to consider when selecting the right motor for a robotic application. There are three common control methods.

- Position control: for applications that require precise positioning, such as robotic arms or CNC machines.

- Speed control: for applications requiring constant or variable speed, such as conveyors or mobile robots.

- Torque control: for applications requiring precise force control, such as robotic grippers or force-sensitive tasks.

Conclusion

Choosing the right motor for your robotics application is a critical decision that will significantly impact the performance, efficiency, and life of your system. By carefully considering motor type, torque requirements, speed, and control method, you can select the perfect motor to meet the unique needs of your application. With the right motor installed, your robot will be able to meet the challenges of today's rapidly evolving robotics world, driving innovation and advancement in countless industries and applications.

Leave a Comment